Agitator Dryers:

Strong together for innovative sewage sludge drying

Collaboration to complete the offering

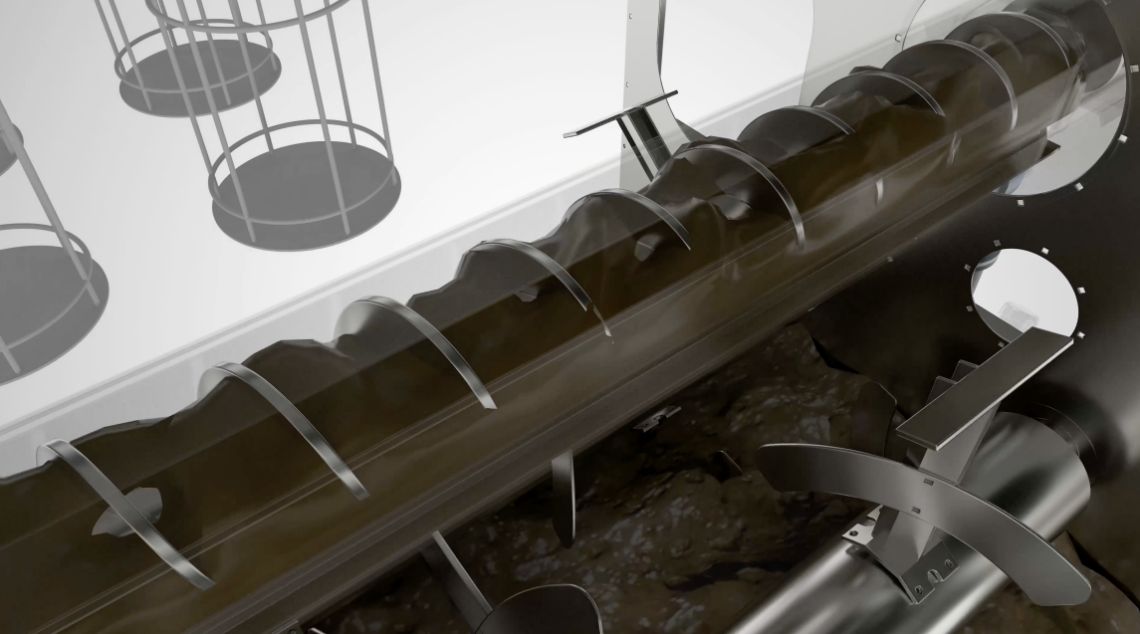

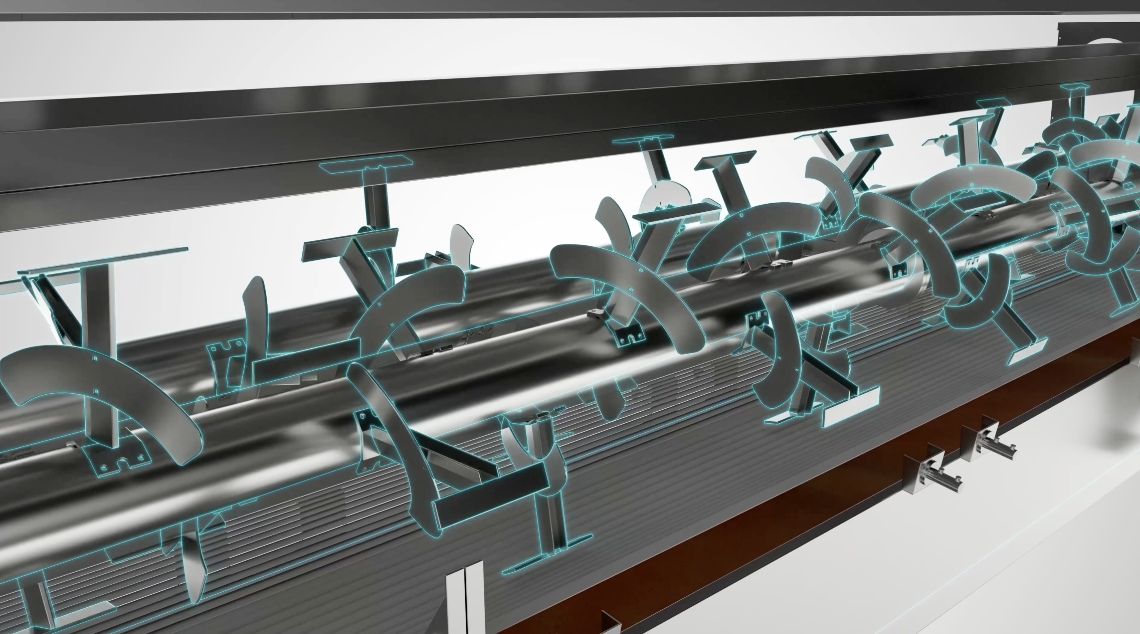

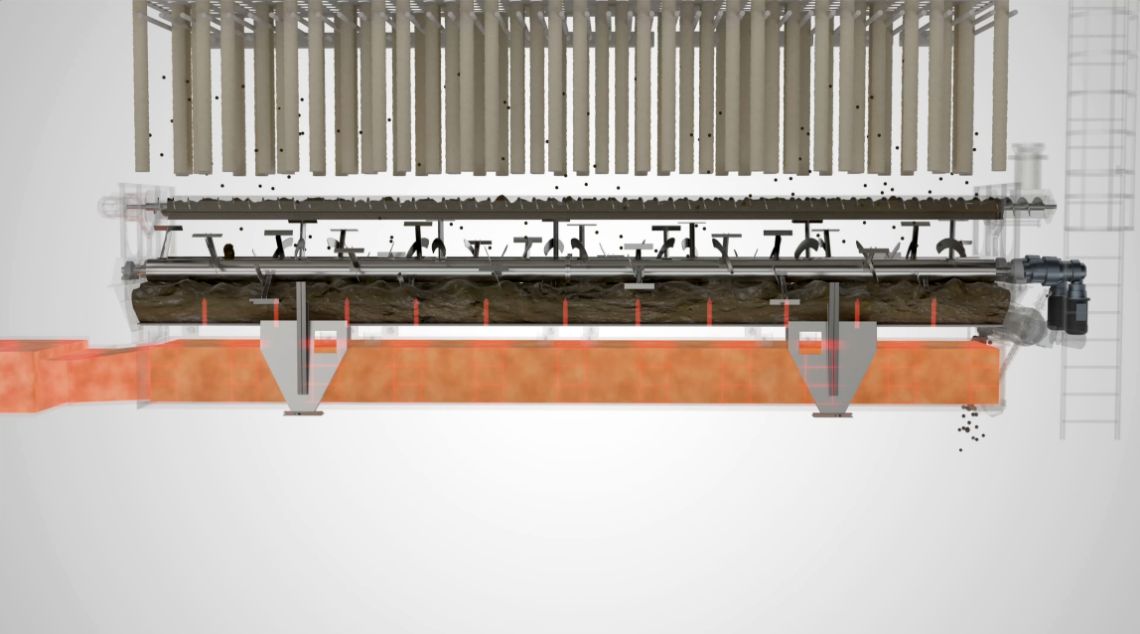

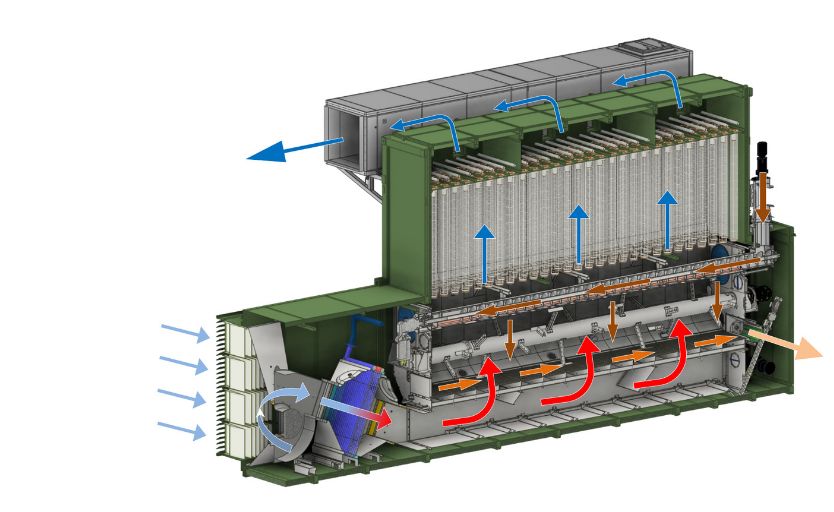

The convection agitator dryers, an innovative development of Gausling Engineering in cooperation with ProTesCa, an established company in the field of environmental technology, set new standards in efficiency and performance. The drying process is accomplished by a combination of heat transfer by convection and mechanical agitation by an agitator. These dryers provide highly effective solutions for drying sewage sludge and unseparated liquid digestate, ensuring a fast and uniform drying process.

The technical advantages:

No adhesive phase, optimal drying:

Unlike conventional methods, our agitated dryers prevent the dreaded sticky phase. This is when sludge hardens like concrete. Ideal conditions are created by a dry “bed”.

Highest efficiency due to large surface area:

Our agitators provide a larger drying area, resulting in remarkably high efficiency. With supply air at 85°C and exhaust air at 30°C, we achieve optimum drying results.

Exhaust filtration is airtight:

Our filter vessels are completely lined with stainless steel and welded airtight to ensure that the exhaust air is saturated between 98% and 100% rel. Effectively filter moisture.

Innovative dust cleaning:

Our patent-pending Jet Pulsee compressed air filter cleaning process ensures reliable cleaning, even with wet dusts.

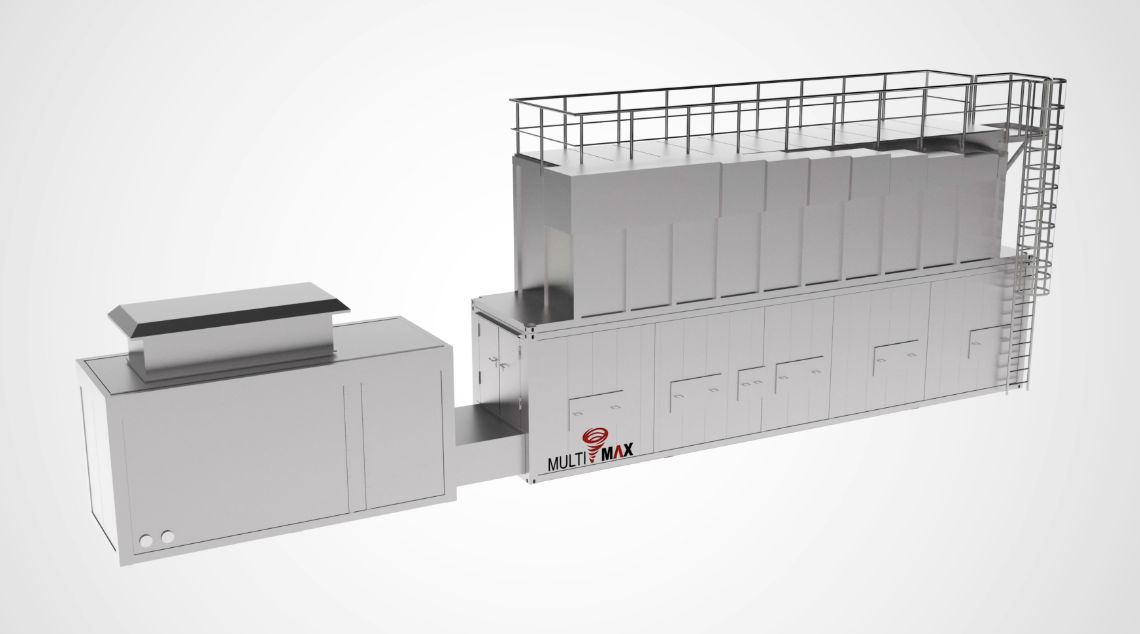

Customized containers:

Our specially designed containers with 100mm sound and heat insulation provide optimal conditions. Inside, they are completely clad in stainless steel, including all contact-related components.

Climate-neutral drying:

Integrated heat pumps use CO2 as a refrigerant, generating 3.5 – 4 KW of heat from 1KW of electricity and heating the required water to 90°C. So you dry environmentally friendly with green electricity.

Your sustainable solution without heat:

Looking for a drying solution without an existing heating system? We got the solution! Our dryers include built-in heat pumps that use CO2 as a refrigerant. From 90 KW to 1000 KW, they generate climate-neutral heat with green electricity, enabling efficient and environmentally friendly drying – CO2 savings and cost reduction included.

Our dryers for every need:

- MultiMax 300: Drying rates from 100 – 300 Kg/hr.

- MultiMax 500: Drying rates of 400 – 500 Kg/hour.

- MultiMax 700: Drying rates of 600 – 700 Kg/hour.

- MultiMax 1000: Drying rates of 800 – 1000 Kg/hour.

Unsure which drying system is right for you?

Contact us

We are Here for you

Do You Have Questions? Our team will be happy to provide information for you.