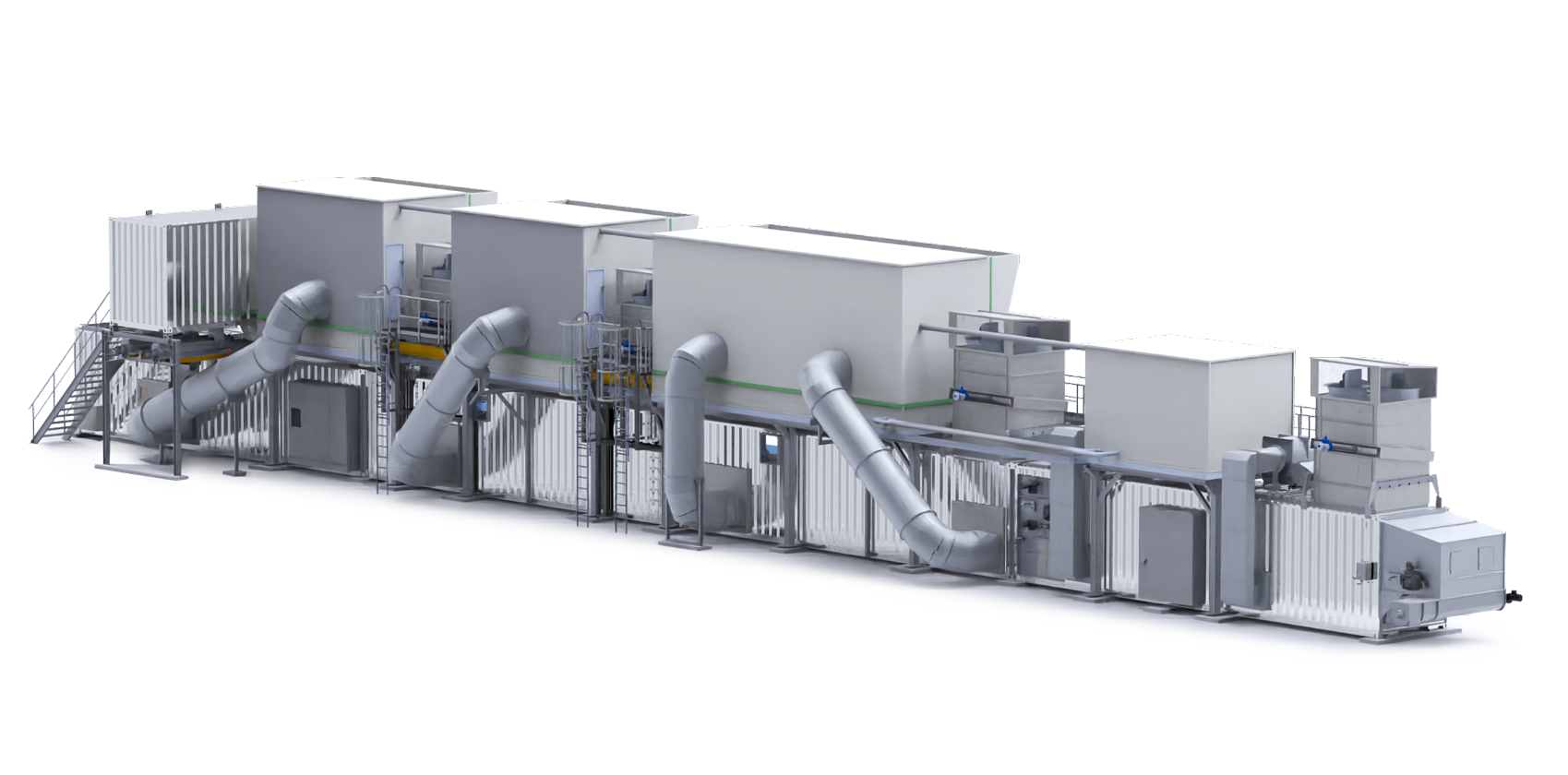

Container-Band-Trockner:

THE BELT DRYER

SETTING NEW STANDARDS

The dryer isn’t IN the container;

the container IS the dryer.

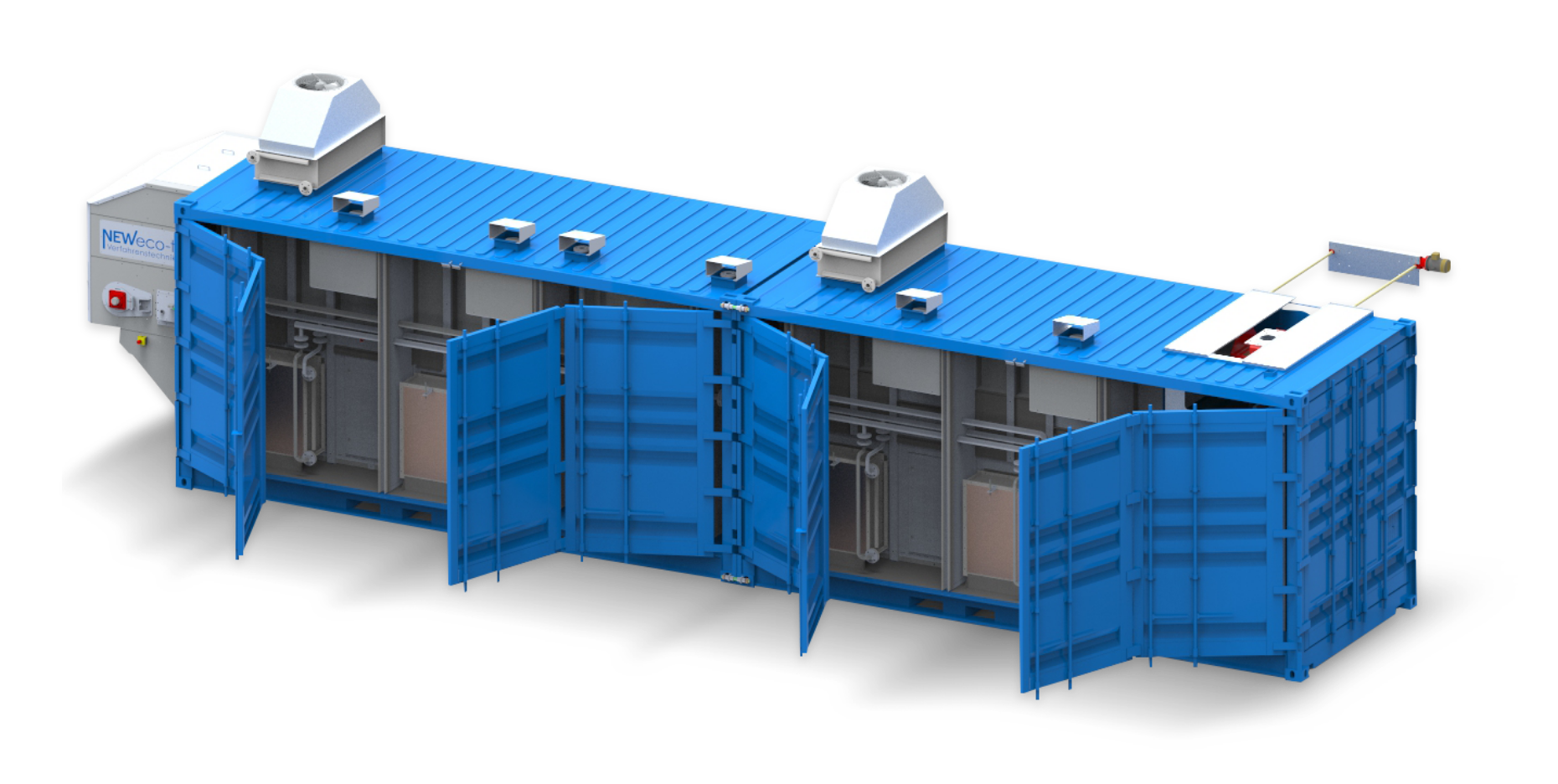

That is what makes the Container-Band-Trockner unique: The shipping container is the load-bearing structure and airflow housing—an integral part of the belt drying system. The Container-Band-Trockner is available in sizes XS to XXXL depending what is needed for the industry and product. Containers can be shortened, placed end to end, or stacked to create the ideal drying system to fit in with upstream and downstream activities. Our modular system offers several advantages:

Easy to transport:

The container format of the Container-Band-Trockner is designed to be transported by flatbed truck, train or ship.

Maximum versatility:

The system can be extended, relocated, or reconfigured as you choose—with no reduction in quality.

100% weatherproof:

The Container-Band-Trockner is the first belt dryer in the world to come in its own building!

Quickly ready for operation:

The Container-Band-Trockner is prefabricated and tested at our factory. Once on site, it is ready for action within a few days.

The technical advantages:

Exterior:

GOES WITH ANYTHING

Maximum versatility:

Our custom designs make the system suitable for all kinds of applications

Amazing adaptability:

The modules can be arranged according to needs and customer requests

Ideal compatibility:

Upstream and downstream areas available (as option) for all areas of application

COLOR SPLASH:

Painted in your preferred color

Interior:

BEAUTY ON THE INSIDE

Optimum drying:

Air is channeled from top to bottom for: minimal dust, stable product conveyance, and uniform dehydration

Secure product conveyance:

Our specially designed temperature-resistant fabric belt optimally conveys products through the drying process

Even product intake:

Intake and dosing units using different systems, like the double auger or floor conveyor, evenly spread the wet product across the drying belt

Details:

CLEVER OPTIONS

No rust here:

Corrosion resistant paneling inside and out

Save energy:

Use the residual heat from power generators (cogeneration units) and other thermal processes

Keeping it clean:

Integrated belt cleaning system

Move it along:

Turning system to accelerate the drying process

Models:

Our dryers at a glance

The Container-Band-Trockner is available in different versions that are ideally adapted to their uses:

Container-Band-Trockner:

The all-rounder—the basic model in our compact belt dryer range with several additional modules available for specific processes.

Container-Band-Trockner WT:

Versatile—suited to all throughput volumes and drying requirements.

Container-Band-Trockner ALLinDRYer:

Practical—equipped with large infeed containers for industrial and agricultural bulk materials / goods.

Container-Band-Trockner Woody:

The giant—with a belt width of 6 meters, this model is made for volume. Ideal for the wood industry.

Container-Band-Trockner SDryer:

For the tricky jobs—equipped with several conveyors and a heat recovery system, among other features.

Container-Band-Trockner Substrator:

The juice extractor—ideal for sustainable nutrient management as part of fertilizer production.

Container-Band-Trockner SEP:

The specialist—reduces volume and dries separated fermentation substrate.

Container-Band-Trockner SSW:

Your recycling assistant—ideal for drying recyclable material or valuable resources.

Binder drying systems:

The Rolls Royce of belt dryers, individually designed for use in the chemical, pharmaceutical and food industries.

Unsure which drying system is right for you?

Contact

We are Here for you

Do You Have Questions? Our team will be happy to provide information for you.